Self-priming pumps and centrifugal pumps differ in their working principles, applications, and design. Below are the key differences between these two types of pumps:

1. Working Principle

Centrifugal Pump: A centrifugal pump operates by utilizing the centrifugal force generated by the rotating impeller. This force increases the pressure of the liquid, causing it to flow from the pump’s inlet to the outlet. Liquid enters the pump through the suction port and is accelerated by the impeller before being discharged.

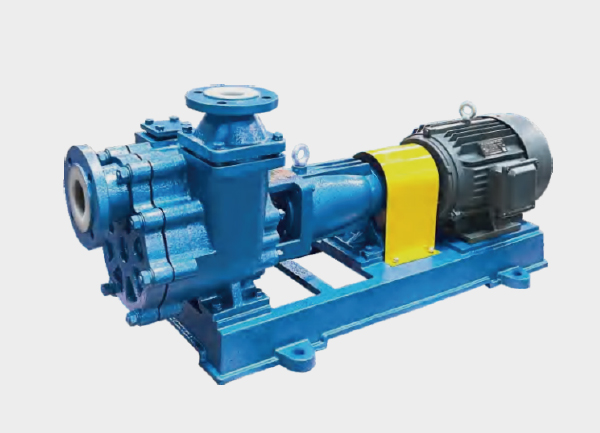

Self-Priming Pump: A self-priming pump works similarly to a centrifugal pump, but with the added feature of being able to automatically prime itself. It can draw in liquid without requiring pre-filled water, thanks to a unique design that expels air or air bubbles, allowing the pump to self-prime and start pumping liquid.

2. Applications

Centrifugal Pump: Widely used for continuous liquid transport, such as water, chemicals, oils, and other liquids. It is ideal for applications requiring steady, uninterrupted flow.

Self-Priming Pump: Perfect for situations where the suction head is higher or water supply is inconsistent. Common applications include well water extraction, irrigation, and rainwater drainage, especially in environments with complex installation conditions.

3. Startup Process

Centrifugal Pump: Typically requires the pump chamber to be primed or filled with liquid before starting, especially when the pump is installed above the water source.

Self-Priming Pump: Can start without prior priming. The pump expels air from the system and automatically draws in liquid, making it more convenient in certain scenarios.

4. Performance Differences

Centrifugal Pump: Known for its stable performance, it is ideal for continuous operation. However, air in the suction line can affect performance and reduce efficiency.

Self-Priming Pump: Can handle liquids with air or bubbles, allowing it to self-prime even in challenging conditions. However, its efficiency may be slightly lower compared to a standard centrifugal pump in certain applications.

5. Structural Differences

Centrifugal Pump: Typically has a simple structure, consisting of a pump casing, impeller, and bearings.

Self-Priming Pump: Features a more complex design, often including special impeller or pump casing modifications to enable the self-priming function.

Conclusion

In summary, centrifugal pumps are ideal for consistent liquid transfer, while self-priming pumps are better suited for applications that require automatic priming or handling fluctuating water sources.