Magnetic drive water pumps (commonly called “magnetic water pumps”) are leak-free fluid transfer devices engineered based on the magnetic coupling transmission principle. Their core advantage is eliminating the shaft seal leakage problem of traditional centrifugal water pumps through non-contact power transfer, making them widely used in industries like chemical processing, pharmaceuticals, environmental protection, food & beverage, and semiconductor manufacturing—especially for transferring water-based fluids, corrosive aqueous solutions, or high-purity water that requires strict sealing to prevent leakage, contamination, or safety hazards.

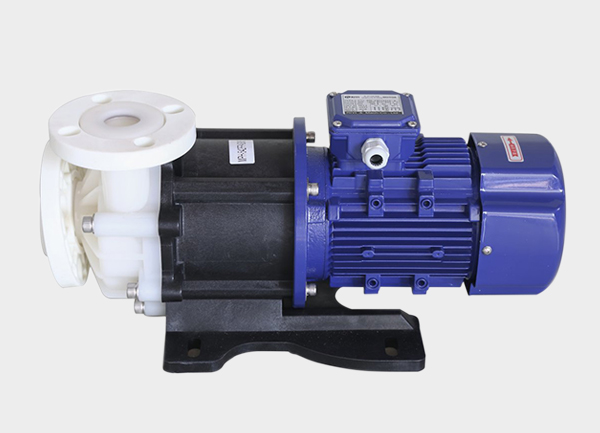

Plastic Magnetic Drive Pump

1. Core Working Principle: How Non-Contact Magnetic Transmission Works

Unlike traditional water pumps that use mechanical shafts to drive impellers, magnetic drive water pumps rely on magnetic force for power transmission. The entire process follows three key stages, forming a seamless “power input → magnetic field transfer → water circulation” cycle:

1.1 Power Input: Generating a Rotating Magnetic Field

When the pump’s motor is activated, it directly drives the outer magnetic rotor (mounted outside the pump’s fluid chamber) to spin at high speed. The outer magnetic rotor is composed of high-performance rare-earth permanent magnets (e.g., neodymium-iron-boron) arranged in a precise polarity sequence. As it rotates, it creates a synchronous rotating magnetic field in the surrounding space—this magnetic field is the “invisible force” that enables power transmission.

1.2 Magnetic Field Penetration: Static Sealing & Torque Transfer

Between the outer magnetic rotor and the inner magnetic rotor (located inside the pump’s water-containing cavity) lies a critical component: the separation sleeve. Made of non-magnetic, high-strength materials (such as 316L stainless steel, titanium alloy, or PTFE/polytetrafluoroethylene), the separation sleeve serves two vital purposes:

- It physically isolates the “power side” (outer magnetic rotor + motor) from the “water side” (inner magnetic rotor + impeller + pump cavity), creating a static seal (no moving seal gaps). This design fundamentally stops water or fluid leakage—a major flaw of traditional pumps with mechanical seals.

- It allows the rotating magnetic field from the outer rotor to pass through unobstructed. The inner magnetic rotor (also fitted with permanent magnets, with polarity matching the outer rotor) is pulled by this magnetic field, generating magnetic torque that drives it to rotate.

1.3 Water Transfer: Centrifugal Force from the Impeller

The inner magnetic rotor is rigidly connected to the pump’s impeller (the core part that moves water). As the inner rotor spins synchronously with the outer rotor (no slippage), the impeller rotates at high speed. This rotation creates strong centrifugal force on the water inside the pump cavity:

- Water is pushed outward to the edge of the impeller by centrifugal force, then flows into the pump’s volute-shaped chamber. As the volute’s cross-sectional area expands, the water’s kinetic energy is converted into pressure energy, and the pressurized water is discharged through the pump’s outlet.

- Meanwhile, the center of the impeller forms a low-pressure zone (since water is pushed outward). Under atmospheric pressure, water from the inlet pipe (e.g., a water tank or pipeline) is continuously sucked into the impeller’s center, completing the “suction → pressurization → discharge” cycle for continuous water transfer.

2. Key Components of Magnetic Drive Water Pumps

The structure of magnetic drive water pumps is optimized for “leak-free operation” and “reliable magnetic transmission.” It consists of five core parts, each with a specific function that works in harmony to ensure stable water transfer:

2.1 Motor: The Power Source

As the pump’s “engine,” magnetic drive water pumps typically use asynchronous motors (available in explosion-proof or standard versions, depending on the application). Its sole role is to drive the outer magnetic rotor to rotate—motor power is matched to the pump’s required head (water lifting height) and flow rate (water transfer volume per unit time) to avoid “decoupling” (slippage between inner and outer rotors due to insufficient power).

2.2 Magnetic Coupler: The Heart of Non-Contact Transmission

The magnetic coupler is made up of the outer magnetic rotor and inner magnetic rotor, and it is the key to non-contact power transfer:

- Outer magnetic rotor: Positioned outside the pump cavity, connected to the motor’s output shaft. Its surface is covered with a stainless steel casing to protect the internal permanent magnets from dust, moisture, or external damage.

- Inner magnetic rotor: Located inside the pump’s water cavity, fixed to the impeller’s shaft. Its surface is often coated with a corrosion-resistant liner (e.g., fluoroplastic or ceramic) to prevent rust or damage from corrosive water (such as acidic/alkaline aqueous solutions).

The two rotors interact via magnetic force, transferring power without physical contact—this eliminates the need for a rotating shaft seal (the main source of leakage in traditional pumps).

2.3 Separation Sleeve: The Leak-Proof Barrier

The separation sleeve is the “wall” that keeps water inside the pump cavity. To perform this role effectively, it must meet two requirements:

- Non-magnetic property: It cannot block the magnetic field—if the sleeve were magnetic, it would absorb the magnetic force, preventing the inner rotor from rotating.

- Corrosion & pressure resistance: It must withstand the pressure of the water inside the pump and resist corrosion from water (especially for applications like transferring seawater, chemical wastewater, or acidic cleaning solutions). Common materials include:

- 316L stainless steel: For general corrosive water (e.g., mild chemical solutions).

- Titanium alloy: For high-pressure, highly corrosive environments (e.g., industrial acid wastewater).

- PTFE: For small-capacity pumps or ultra-corrosive fluids (e.g., strong acids like hydrochloric acid).

2.4 Pump Body & Impeller: The Water-Moving Core

- Pump body: Usually made of stainless steel, fluoroplastic (PVDF), or cast iron (for non-corrosive water like tap water). Its internal volute shape is designed to efficiently convert the impeller’s rotational energy into water pressure, ensuring smooth water flow to the outlet.

- Impeller: The “fan blade” that directly contacts water. Made of materials matching the pump body (e.g., fluoroplastic impellers for corrosive water), its blade shape (closed, semi-open, or open) is tailored to the water’s viscosity (e.g., thick wastewater vs. clean water) and whether it contains small particles (e.g., sand in groundwater).

2.5 Bearings & Shaft: Rotational Support

- Bearings: These support the inner magnetic rotor and impeller, ensuring stable rotation. Since they are in direct contact with water, they are made of wear-resistant, corrosion-resistant materials like silicon carbide (SiC) or ceramic. They rely on the flowing water for lubrication and cooling—dry operation (running without water) can damage them quickly.

- Shaft: A stainless steel rod that connects the inner magnetic rotor and impeller. It must be rigid and straight to avoid vibration during rotation, which could cause noise or damage to other parts.

3. Core Advantages of Magnetic Drive Water Pumps

Compared to traditional centrifugal water pumps (with mechanical seals or packed seals), magnetic drive water pumps offer unique benefits that make them ideal for specific applications:

3.1 Absolute Leak-Free Operation

The static seal of the separation sleeve eliminates the risk of water leakage. This is critical for:

- Transferring toxic or hazardous water (e.g., chemical wastewater, heavy metal-containing water) to prevent environmental pollution.

- High-purity water applications (e.g., semiconductor manufacturing, pharmaceutical water treatment) to avoid contamination.

- Food & beverage industries (e.g., juice, dairy processing) to meet hygiene standards (no seal wear particles mixing into water).

3.2 Low Maintenance Requirements

Traditional pumps require frequent replacement of mechanical seal parts (e.g., seal rings, springs) due to wear. Magnetic drive water pumps have no such moving seal components—routine maintenance only involves:

- Checking if the bearings are worn (via unusual noise or reduced flow).

- Inspecting the separation sleeve for cracks or corrosion.

- Ensuring the magnetic rotors are not demagnetized (signaled by reduced head/flow).

This reduces maintenance time and costs, especially for pumps installed in hard-to-reach locations (e.g., underground water tanks or chemical tanks).

3.3 Quiet & Stable Operation

Since there is no physical contact between the inner and outer magnetic rotors (no friction), magnetic drive water pumps run much quieter than traditional pumps. The smooth impeller design also minimizes water turbulence, further reducing noise—making them suitable for indoor applications (e.g., laboratory water circulation or residential water supply systems).

3.4 Strong Corrosion Resistance

By choosing materials like stainless steel, titanium alloy, or fluoroplastic for parts in contact with water, magnetic drive water pumps can handle a wide range of corrosive water types, including:

- Acidic water (e.g., pH 1–4, such as pickling wastewater).

- Alkaline water (e.g., pH 10–14, such as detergent solutions).

- Saline water (e.g., seawater for marine applications).

4. Limitations to Consider

While magnetic drive water pumps offer many advantages, they are not suitable for all water transfer scenarios. Key limitations include:

4.1 Eddy Current Loss

When the rotating magnetic field passes through a metal separation sleeve (e.g., stainless steel), it generates eddy currents (small electrical currents) in the sleeve. These currents cause energy loss (typically 5–15% of motor power), reducing the pump’s efficiency. To mitigate this, small pumps often use PTFE sleeves (no eddy currents), while large pumps use thinner metal sleeves or low-resistance materials (e.g., titanium alloy).

4.2 Sensitivity to Air & Dry Operation

- Air binding: If air enters the pump cavity (e.g., from an unprimed inlet pipe), the impeller cannot generate enough centrifugal force to move water—this is called “air binding,” and the pump will not transfer water until the air is purged.

- Dry operation: Running the pump without water (even for a few minutes) will cause the bearings to overheat and wear out (since there is no water for lubrication). It can also demagnetize the magnetic rotors, permanently damaging the pump.

4.3 Limited Head & Flow

The magnetic torque between the inner and outer rotors has a maximum limit. This means magnetic drive water pumps are best for low-to-medium head applications (usually ≤100 meters) and medium flow rates (typically ≤100 m³/h). They are not suitable for high-head scenarios (e.g., water supply to tall buildings over 100 meters) or high-viscosity fluids (e.g., thick sludge), as these can cause rotor decoupling (slippage).

4.4 Higher Initial Cost

Due to the use of rare-earth permanent magnets (e.g., neodymium-iron-boron) and corrosion-resistant materials, magnetic drive water pumps have a higher upfront cost than traditional mechanical seal pumps (usually 30–50% more expensive). However, their lower maintenance costs and longer lifespan (5–8 years vs. 3–5 years for traditional pumps) often make them more cost-effective in the long run.

5. Typical Applications of Magnetic Drive Water Pumps

Magnetic drive water pumps excel in scenarios where leakage prevention, corrosion resistance, or hygiene is critical. Common applications include:

5.1 Chemical Industry

- Transferring corrosive aqueous solutions (e.g., sulfuric acid solution, sodium hydroxide solution) and chemical wastewater.

- Circulating cooling water in chemical reactors (no leakage to protect equipment and workers).

5.2 Pharmaceutical & Healthcare

- Transferring high-purity water (e.g., distilled water, injection water) for drug manufacturing.

- Circulating cleaning solutions in medical equipment (no contamination from seal wear).

5.3 Environmental Protection

- Treating industrial wastewater (e.g., heavy metal-containing water, 印染 wastewater) to prevent leakage and soil/water pollution.

- Circulating water in sewage treatment plants (corrosion resistance to handle acidic/alkaline wastewater).

5.4 Food & Beverage

- Transferring drinking water, fruit juice, dairy products, or edible oil (no seal particles to ensure food safety).

- Circulating cleaning water in food processing lines (hygienic, easy to clean).

5.5 Semiconductor & Electronics

- Supplying ultra-pure water (UPW) for semiconductor chip manufacturing (no contamination to protect sensitive components).

- Cooling water circulation for electronic equipment (quiet operation, no leakage).

6. How Magnetic Drive Water Pumps Compare to Traditional Centrifugal Water Pumps

To help you choose the right pump, here’s a clear comparison between magnetic drive water pumps and traditional mechanical seal centrifugal water pumps:

| Feature | Magnetic Drive Water Pump | Traditional Mechanical Seal Water Pump |

|---|---|---|

| Seal Type | Static seal (separation sleeve) | Dynamic seal (mechanical seal/packed seal) |

| Leakage Risk | Absolute no leakage | Leakage possible after 6–12 months (seal wear) |

| Maintenance Cost | Low (no seal replacement) | High (seal parts replaced every 6–12 months) |

| Efficiency | Slightly lower (5–15% eddy current loss) | Higher (no eddy current loss) |

| Noise Level | Low (≤60 dB) | Higher (65–75 dB, due to mechanical friction) |

| Corrosion Resistance | Excellent (customizable materials) | Limited (seals prone to corrosion) |

| Suitable Fluids | Corrosive water, high-purity water, toxic fluids | Clean water, low-corrosion fluids |

| Initial Cost | Higher (30–50% more) | Lower |

| Lifespan | 5–8 years | 3–5 years |

In summary, magnetic drive water pumps are the top choice for applications where leakage, corrosion, or contamination is a critical concern. While they have a higher initial cost and limited head/flow, their long-term reliability, low maintenance, and leak-free performance make them a valuable investment for industries like chemicals, pharmaceuticals, and food processing.