Chemical dosing pumps, also known as metering pumps, are specialized fluid-handling devices designed for precise chemical delivery. They are widely used in water treatment (municipal & industrial), chemical reactions, pharmaceutical preparation, and environmental applications such as flue gas desulfurization (FGD) and denitrification. Their primary function is to add chemicals accurately and proportionally, preventing under- or overdosing, which could compromise process efficiency or cause secondary pollution.

1. Core Working Principle of Chemical Dosing Pumps

A chemical dosing pump is essentially a positive displacement pump. It works by periodically changing the pump chamber volume, generating suction and discharge pressure to draw, pressurize, and deliver chemicals. The pump design ensures precise flow control.

Based on the type of driving mechanism, common dosing pumps include diaphragm pumps, plunger pumps, and gear pumps.

1.1 Diaphragm Dosing Pumps (Mechanical / Hydraulic Diaphragm)

Structure Components:

Motor, eccentric cam (or camshaft), connecting rod

Elastic diaphragm (PP/PVDF/PTFE for corrosion resistance)

Inlet/outlet check valves (prevent backflow)

Stroke adjustment mechanism

Working Process (Mechanical Diaphragm Example):

Suction Stroke: Motor rotates the eccentric cam → moves the diaphragm away from the pump chamber → chamber volume increases → internal pressure drops → inlet valve opens, outlet valve closes → chemical is drawn into the chamber.

Discharge Stroke: Cam pushes diaphragm toward the chamber → volume decreases → pressure rises → inlet valve closes, outlet valve opens → chemical is discharged.

Precise Control: Flow rate is adjusted via stroke length or motor speed, achieving high accuracy (±0.5%–3%).

Mechanical vs. Hydraulic Diaphragm:

Hydraulic diaphragm pumps use a hydraulic oil chamber to transmit force to the diaphragm, reducing direct wear, extending diaphragm life, and allowing higher pressure operation (≥10 MPa). However, the structure is more complex and costlier.

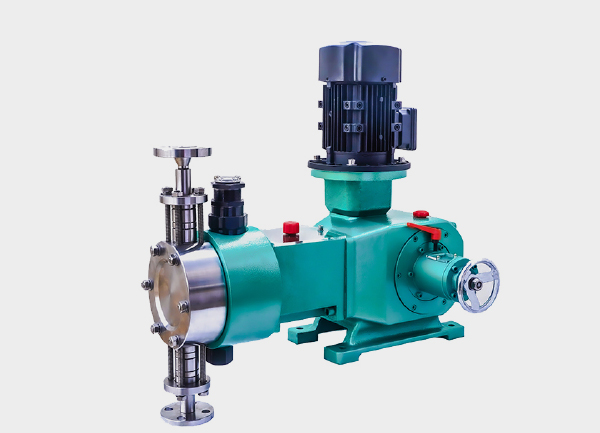

1.2 Plunger Dosing Pumps

Structure Components:

Motor, crankshaft, plunger (316 stainless steel)

Pump cylinder (corrosion-resistant)

Check valves, seals

Working Process:

Suction: Plunger moves outward → cylinder volume increases → inlet valve opens, outlet valve closes → chemical enters cylinder.

Discharge: Plunger moves inward → volume decreases → inlet valve closes, outlet valve opens → chemical is discharged.

Features:

Extremely high accuracy (±0.1%–1%) and high pressure capability

Seals wear over time, especially with corrosive chemicals → may cause minor leaks

Best suited for non-corrosive, high-viscosity fluids like lubricants or syrups

1.3 Gear Dosing Pumps

Structure Components:

Motor, pair of meshing gears (driven + driven)

Pump housing, inlet/outlet

Working Process:

Motor rotates the gears → the volume between gear teeth periodically increases (suction) and decreases (discharge) → chemical is pumped.

Features:

Suitable for high-viscosity chemicals (pastes, gels)

Lower accuracy (±3%–5%)

Gear teeth can jam with particulates → requires filtration

2. Key Advantages of Chemical Dosing Pumps

Chemical dosing pumps excel in precision, corrosion resistance, stability, and controllability, making them ideal for chemical applications.

2.1 High Accuracy for Proportional Dosing

Importance: Proper dosing is critical. For example, in wastewater treatment, overdosing flocculants (PAC) increases sludge volume, while underdosing prevents sedimentation.

Control Method: Stroke or motor speed adjustment allows precise flow setting (from 0.1 L/h to over 1000 L/h), with accuracy ±0.1%–5%.

Applications: Pharmaceutical ingredient dosing, chemical reaction catalysts

2.2 Strong Corrosion Resistance

Materials: Pumping components use chemical-resistant materials:

Mild corrosives: PP, PVDF

Strong acids/oxidizers: PTFE

High-temperature/high-pressure: 316L stainless steel, Hastelloy

Benefits: Protects pump integrity and prevents chemical degradation

2.3 Automation and System Integration

Function: Can link with sensors and PLCs for demand-based dosing

Example: pH sensor triggers PLC → adjusts dosing pump speed → maintains target pH automatically

Benefit: Reduces manual error, operational costs, and ensures consistent process parameters

2.4 Stable Operation and Low Maintenance

Diaphragm pumps eliminate piston-seal friction → diaphragm lasts 1–3 years

Leak-free design: isolates chemicals from drive components → safer operation, less environmental risk

Adaptable to various conditions: low-flow/high-pressure or high-viscosity/low-pressure systems

2.5 Compact Size and Flexible Installation

Pumps are available in compact vertical or horizontal designs, some hand-sized

Can be installed directly on chemical drums (“drum-mounted” designs)

Suitable for labs, factories, or outdoor installations