In the papermaking industry, a wide range of chemical liquids—such as sodium hydroxide, sodium hypochlorite, hydrogen peroxide, sulfuric acid, and rosin sizing agents—are used throughout the production process. These chemicals create a highly corrosive and high-temperature working environment, where traditional mechanical seal pumps often face serious leakage, seal failure, and bearing wear problems. Such failures not only contaminate pulp systems but also lead to costly downtime and maintenance.

🔧 Challenges in the Paper Industry

Highly Corrosive Liquids – Alkalis, acids, and bleaching agents can severely corrode metal pump components.

Frequent Seal Leakage – Mechanical seals tend to age or seize due to crystallization, resulting in chemical leakage.

High Maintenance and Downtime Costs – Seal replacement and bearing lubrication require frequent shutdowns.

Environmental and Safety Risks – Chemical leakage contaminates the production environment and increases regulatory pressure.

⚙️ Advantages of Magnetic Drive Pumps

Seal-Free Design — No Leakage Risk

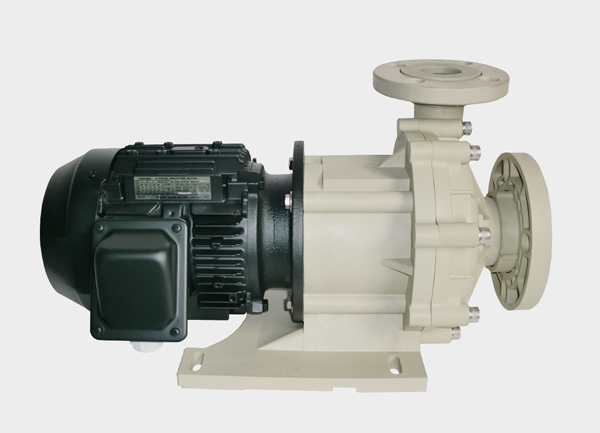

Magnetic coupling transfers power without mechanical contact, ensuring a completely sealed structure and zero leakage during operation.Excellent Corrosion Resistance

Materials such as fluoroplastics, stainless steel, and engineered plastics enable the pump to handle acids, alkalis, and oxidizing chemicals safely.Low Maintenance and Long Service Life

The contact-free transmission mechanism reduces friction and wear, extending the overall service life of the pump.Stable Operation for Continuous Processes

Ideal for bleaching, chemical recovery, and caustic recycling systems that demand long-term stable operation.

📈 Typical Applications

Bleaching Section: For safe transfer of sodium hypochlorite and hydrogen peroxide without contaminating pulp.

Caustic Recovery System: Suitable for high-temperature, alkaline fluid circulation.

Chemical Preparation System: Ensures precise metering and safe delivery of additives.

✅ Conclusion

With their leak-free, corrosion-resistant, and low-maintenance design, magnetic drive pumps have become a reliable choice for chemical fluid handling in paper manufacturing. They help paper mills enhance operational safety, reduce environmental risks, and achieve higher production efficiency.