In the industrial fluid transfer field, pumps are essential for moving liquids efficiently and safely. However, many users often confuse centrifugal pumps with self-priming pumps because they look similar in design.

So, what’s the real difference between them, and how do you select the right one for your application? Let’s explore in detail.

🔹 1. What Is a Centrifugal Pump?

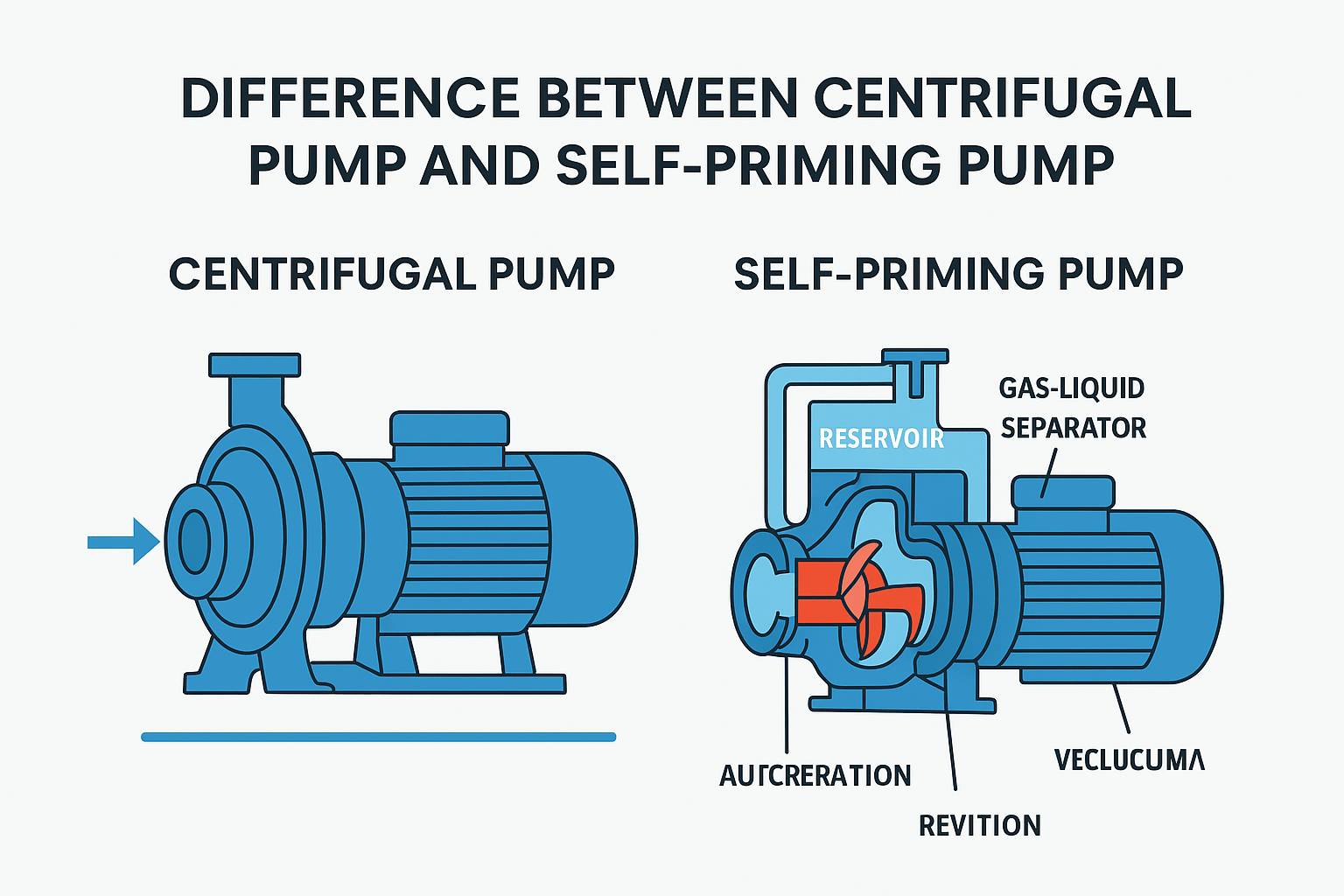

A centrifugal pump is a hydraulic machine that uses the centrifugal force generated by the rotation of the impeller to move liquid. When the impeller rotates, it increases the liquid’s velocity and converts kinetic energy into pressure energy, pushing the liquid from the pump inlet to the outlet.

👉 Important: Before starting, a centrifugal pump must be filled with liquid (primed) or equipped with a vacuum priming system.

If the pump runs dry, it cannot create suction, and the impeller will be damaged.

🔹 2. What Is a Self-Priming Pump?

A self-priming pump is a specially designed centrifugal pump that can automatically remove air from the suction line and draw liquid into the pump body.

It has a built-in liquid reservoir and gas–liquid separation chamber, which allow it to automatically prime without manually filling water each time.

👉 Once the pump body contains enough liquid, it can re-prime automatically after each shutdown, making it ideal for intermittent or mobile operations.

🔹 3. Structural Differences

| Feature | Centrifugal Pump | Self-Priming Pump |

|---|---|---|

| Structure | Simple impeller and volute casing | Includes liquid reservoir, recirculation channel, and air separator |

| Priming Requirement | Must be filled with liquid before startup | Automatically primes without manual filling |

| Suction Inlet | Usually horizontal | Often side-mounted or bottom suction |

| Internal Sealing | Moderate | High sealing required for vacuum retention |

🔹 4. Working Principle Comparison

Centrifugal Pump Principle:

The rotating impeller generates centrifugal force, which pushes liquid outward. The pressure difference created between the inlet and outlet allows fluid to flow continuously.

Requires the pump chamber to be full of liquid before operation.Self-Priming Pump Principle:

At startup, the retained liquid in the pump mixes with air in the suction line. This mixture is then separated in the gas–liquid chamber, creating a vacuum that draws more liquid from the source tank.

Automatically removes air and continues pumping.

🔹 5. Performance & Application Comparison

| Parameter | Centrifugal Pump | Self-Priming Pump |

|---|---|---|

| Suction Lift | Typically ≤ 5 meters | Up to 6–8 meters |

| Startup Method | Requires priming | Automatic self-priming |

| Flow & Head | Higher | Moderate |

| Efficiency | High | Slightly lower |

| Maintenance | Easier | Slightly more complex |

| Common Uses | Industrial processes, cooling systems, chemical transfer | Drainage, irrigation, wastewater, portable transfer, marine pumps |

🔹 6. How to Choose Between Them

Choose a centrifugal pump if your system has a continuous liquid supply, low installation height, and stable operating conditions.

Choose a self-priming pump if your system involves frequent starts and stops, low liquid levels, or suction lines that easily trap air.

✅ 7. Key Takeaway

A centrifugal pump needs to be filled before operation, while a self-priming pump can automatically draw liquid and remove air — simple, efficient, and reliable.