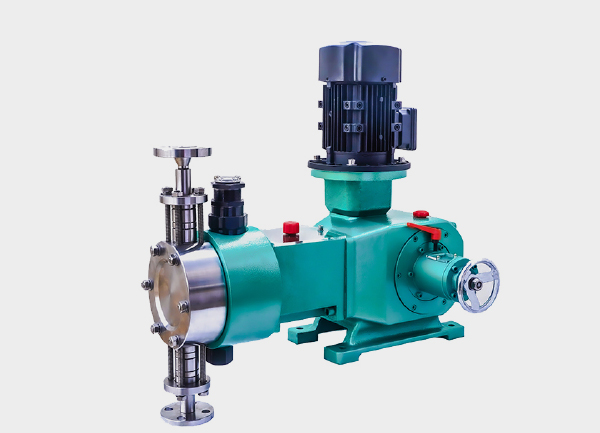

Dosing pumps (also known as metering pumps) are precision equipment designed to deliver accurate amounts of chemicals or additives into a process stream. They are widely used in water treatment, chemical processing, pharmaceuticals, and environmental protection.

Despite their reliability, dosing pumps may experience various operational issues that affect performance, accuracy, and safety.

These can be grouped into seven major categories:

Inaccurate flow rate

Start-up failure

Leakage

Abnormal noise or vibration

Blockage or crystallization

Motor overheating

Control system failure

Below is a detailed analysis of each problem, its root causes, and practical troubleshooting methods.

1. Inaccurate Flow Rate (Most Common Issue)

Since dosing pumps are designed for precise metering, any deviation in flow rate directly affects chemical dosing efficiency — causing overdosing (waste, contamination) or underdosing (ineffective treatment).

| Observed Issue | Possible Causes | Inspection & Troubleshooting |

|---|---|---|

| Flow rate lower than set value | 1. Air trapped in pump head or suction line. 2. Blocked or worn check valves (valve seat wear or debris). 3. Damaged diaphragm or plunger seal. 4. Incorrect stroke/frequency setting. 5. Excessive suction lift or suction resistance. | 1. Vent trapped air via air-release valve; check all suction fittings. 2. Clean or replace check valves. 3. Inspect diaphragm/plunger and replace if leaking. 4. Recalibrate stroke length or frequency. 5. Shorten suction piping and clean the inlet filter. |

| Flow rate higher than set value | 1. Check valve not closing tightly (wear or debris). 2. Stroke/frequency control malfunction. 3. Internal leakage inside pump head. | 1. Replace worn valve seats or O-rings. 2. Check signal stability (4–20 mA / pulse). 3. Replace internal seals if leakage is found. |

| Flow fluctuation or instability | 1. Chemical viscosity or temperature variation. 2. Unstable suction tank level. 3. Incorrect PID control parameters. | 1. Verify liquid properties within pump limits (≤500 cP, ≤80°C). 2. Maintain stable tank level; install level sensor if needed. 3. Tune PID parameters for smoother dosing. |

2. Pump Fails to Start

If the pump does not start or stops immediately after starting, the issue is usually electrical or mechanical.

| Observed Issue | Possible Causes | Inspection & Troubleshooting |

|---|---|---|

| No response (no motor sound) | 1. Power supply failure or loose wiring. 2. Motor overload protection tripped. 3. Control circuit fault (switch, contactor, or PLC). | 1. Measure power voltage (220V/380V). 2. Reset thermal relay and inspect for mechanical blockage. 3. Check switches, relays, and control signals. |

| Motor hums but doesn’t rotate | 1. Mechanical jamming (foreign particles, seized bearings). 2. Rotor jam or burnt motor winding. | 1. Disassemble pump head, clean, and free the mechanism. 2. Measure winding resistance; repair or replace motor if faulty. |

3. Chemical Leakage (Environmental and Safety Concern)

Leaks typically occur at sealing points due to material degradation, improper installation, or chemical corrosion.

| Leak Location | Possible Causes | Inspection & Troubleshooting |

|---|---|---|

| Inlet/outlet connections | 1. Worn or damaged gaskets. 2. Loose pipe fittings. 3. Incompatible pipe materials. | 1. Replace gaskets with chemical-resistant types (e.g., Viton). 2. Tighten fittings evenly. 3. Use compatible materials such as PVDF or 316L stainless steel. |

| Pump head or diaphragm area (diaphragm pumps) | 1. Diaphragm rupture or aging. 2. Loose bolts. 3. Cracked pump head due to corrosion or impact. | 1. Replace diaphragm with PTFE type for corrosive fluids. 2. Retighten cover bolts evenly. 3. Replace cracked pump head. |

| Shaft seal area (plunger or gear pumps) | 1. Worn packing or mechanical seal. 2. Misaligned installation. 3. Shaft wear. | 1. Replace seals; lubricate packing if used. 2. Re-align mechanical seal faces. 3. Repair or replace worn shafts. |

4. Abnormal Noise or Vibration (Early Warning of Mechanical Failure)

A properly running dosing pump should produce less than 75 dB of noise.

Unusual sounds or vibrations indicate mechanical or hydraulic issues.

| Type of Noise | Likely Cause | Corrective Actions |

|---|---|---|

| “Hissing” or “bursting” sound | Cavitation due to low suction pressure or clogged inlet. | Reduce suction lift, clean suction filter, maintain fluid level above inlet. |

| “Buzzing” with vibration | Worn motor bearings, loose mounting bolts, or misalignment. | Replace bearings, tighten bolts, re-align couplings (≤0.1 mm tolerance). |

| “Knocking” sound | Loose or worn valve parts, or debris in pump head. | Clean check valves, replace damaged parts, remove debris. |

5. Chemical Blockage or Crystallization

Common in concentrated or temperature-sensitive solutions such as PAC, PAM, or calcium chloride.

| Observed Issue | Possible Causes | Inspection & Troubleshooting |

|---|---|---|

| Flow suddenly drops | 1. Chemical concentration too high (solid precipitation). 2. Residual fluid crystallized after shutdown. 3. Clogged inlet filter. 4. Low ambient temperature. | 1. Dilute chemical concentration per process specs. 2. Flush system with clean water or solvent after shutdown. 3. Clean filters weekly. 4. Use heating or insulation for low-temperature environments. |

| No flow due to valve blockage | Crystals or particles jam check valves. | Disassemble and clean valves; soak in hot water to dissolve crystals if needed. |

6. Motor Overheating

A common issue caused by overload, poor ventilation, or electrical imbalance.

| Observed Issue | Possible Causes | Inspection & Troubleshooting |

|---|---|---|

| Motor overheats and trips | 1. Pump overloaded (excessive flow or high backpressure). 2. Mechanical friction (foreign particles or worn bearings). | 1. Adjust stroke/frequency to rated flow. 2. Remove blockages and replace bearings. |

| Motor hot but not tripping | 1. Cooling failure (fan damage, blocked vents). 2. Aged or moisture-damaged windings. | 1. Clean vents, replace fan, ensure ventilation (<40°C). 2. Measure insulation resistance (≥0.5 MΩ); rewind or replace if needed. |

7. Control System Failure (For Automatic Dosing Systems)

Automated dosing pumps linked with pH, flow, or PLC systems may encounter control signal or communication problems.

| Observed Issue | Possible Causes | Inspection & Troubleshooting |

|---|---|---|

| Flow not responding to control signal | 1. Faulty sensor (pH probe or flow sensor). 2. Signal interference or wire breakage. 3. Incorrect controller settings (PID parameters or range). | 1. Calibrate or replace sensors. 2. Check signal wiring and use shielded cables. 3. Reconfigure PID and signal range. |

| Remote control not working | 1. Communication failure (RS485 / Modbus). 2. Controller not switched to remote mode. | 1. Tighten connections and verify communication protocol. 2. Switch mode from “Local” to “Remote” on controller panel. |

Preventive Maintenance for Dosing Pumps

Regular Maintenance

Weekly: Clean suction filters, inspect for leaks.

Monthly: Check diaphragm/seal wear, lubricate motor bearings.

Quarterly: Calibrate actual vs. set flow rate, clean check valves.

Proper Pump Selection

Match pump materials to chemical properties:

Acids: PVDF head + PTFE diaphragm.

High-viscosity fluids: Gear dosing pump preferred.

Correct Operation

Prepare solutions according to specified concentration.

Flush system after shutdown, especially with corrosive or crystallizing fluids.

Avoid dry running to prevent diaphragm damage.

Environmental Adaptation

Avoid direct sunlight or high ambient temperatures.

Use heating or insulation in cold environments to prevent crystallization.

Conclusion

By understanding these common dosing pump problems and following systematic inspection and maintenance routines, operators can greatly reduce downtime and ensure stable, precise, and safe dosing performance in industrial applications.