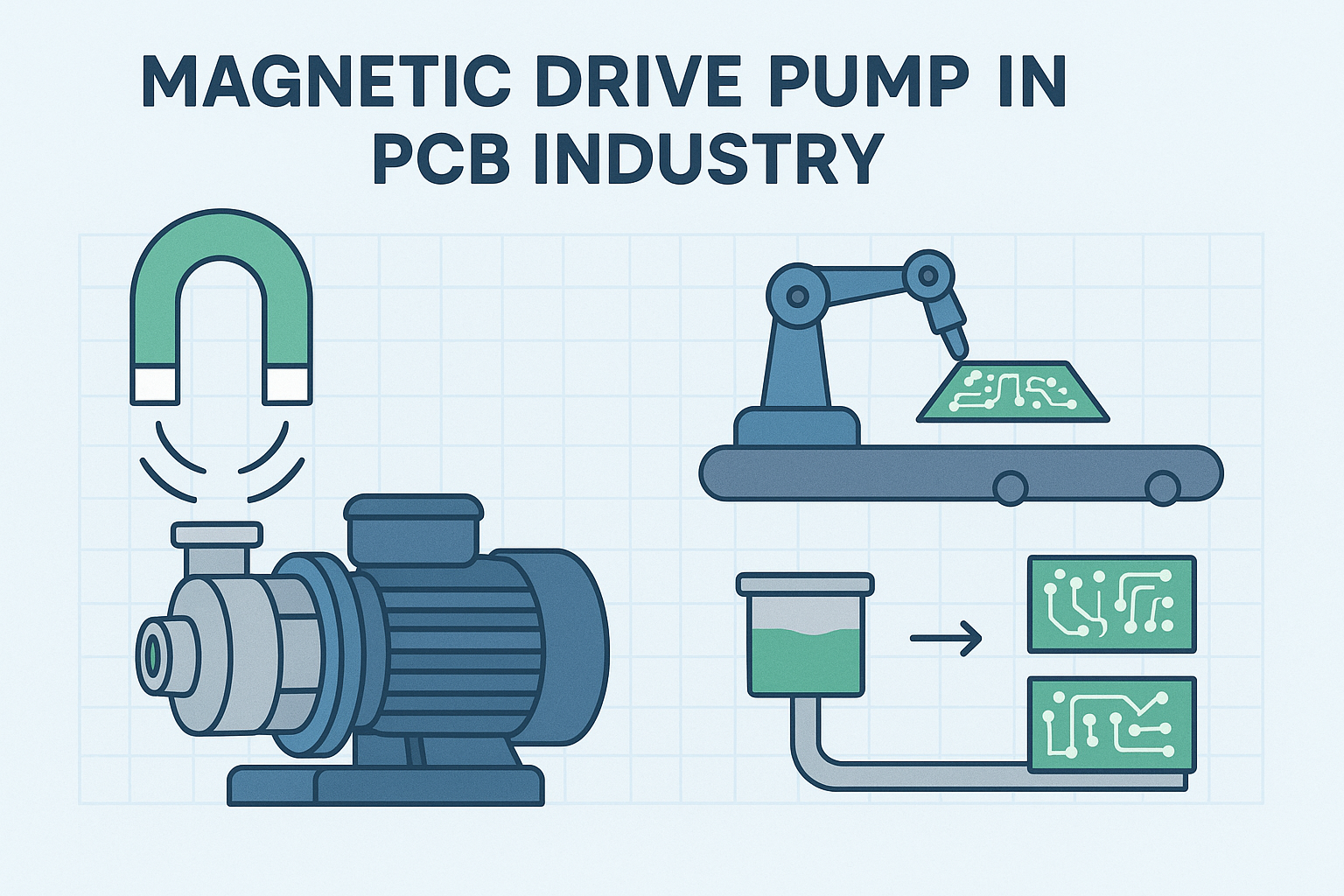

In the printed circuit board (PCB) manufacturing process, every step — from chemical etching to electroplating — relies on precise and stable fluid handling. But how can manufacturers ensure zero leakage, high corrosion resistance, and long-term stability? The answer lies in magnetic drive pumps.

1. Why Magnetic Drive Pumps Are Essential in PCB Production

PCB production involves highly corrosive chemicals such as hydrochloric acid, sulfuric acid, hydrogen peroxide, and alkaline solutions. Traditional mechanical seal pumps often suffer from leakage and frequent seal failures, leading to safety hazards and contamination.

Magnetic drive pumps, on the other hand, use magnetic coupling instead of a mechanical seal. This completely eliminates leakage, ensuring a clean and safe chemical transfer process.

2. Key Applications in PCB Manufacturing

Etching Process: Handles strong acids and oxidants used for copper layer removal.

Electroplating Process: Delivers electrolytes with high purity and chemical stability.

Developing & Stripping Lines: Circulates alkaline developers and stripping solutions.

Rinse & Filtration Systems: Ensures continuous chemical circulation and impurity removal.

3. Technical Advantages

Leak-Free Operation: The sealless design prevents chemical leaks, protecting both workers and equipment.

High Corrosion Resistance: Pumps are made from PP, PVDF, or ETFE, suitable for strong acids and alkalis.

Low Maintenance: No mechanical seals mean fewer failures and lower operating costs.

High Efficiency: Magnetic coupling minimizes power loss while maintaining strong torque transmission.

4. Environmental and Economic Benefits

By preventing chemical leaks and minimizing downtime, magnetic pumps help PCB manufacturers comply with environmental standards and reduce operational costs. Their long lifespan also lowers waste and maintenance frequency.

Conclusion

The magnetic drive pump has become a core fluid-handling solution in modern PCB plants. It ensures chemical safety, production stability, and environmental sustainability — three key pillars for the next generation of intelligent PCB manufacturing.