In industries such as chemical processing, electroplating, pharmaceuticals, and environmental water treatment, fluid transfer is the lifeline of production. But have you ever wondered—can a single “universal” pump handle all types of fluids, from mild solutions to highly corrosive acids? The answer is clearly no.

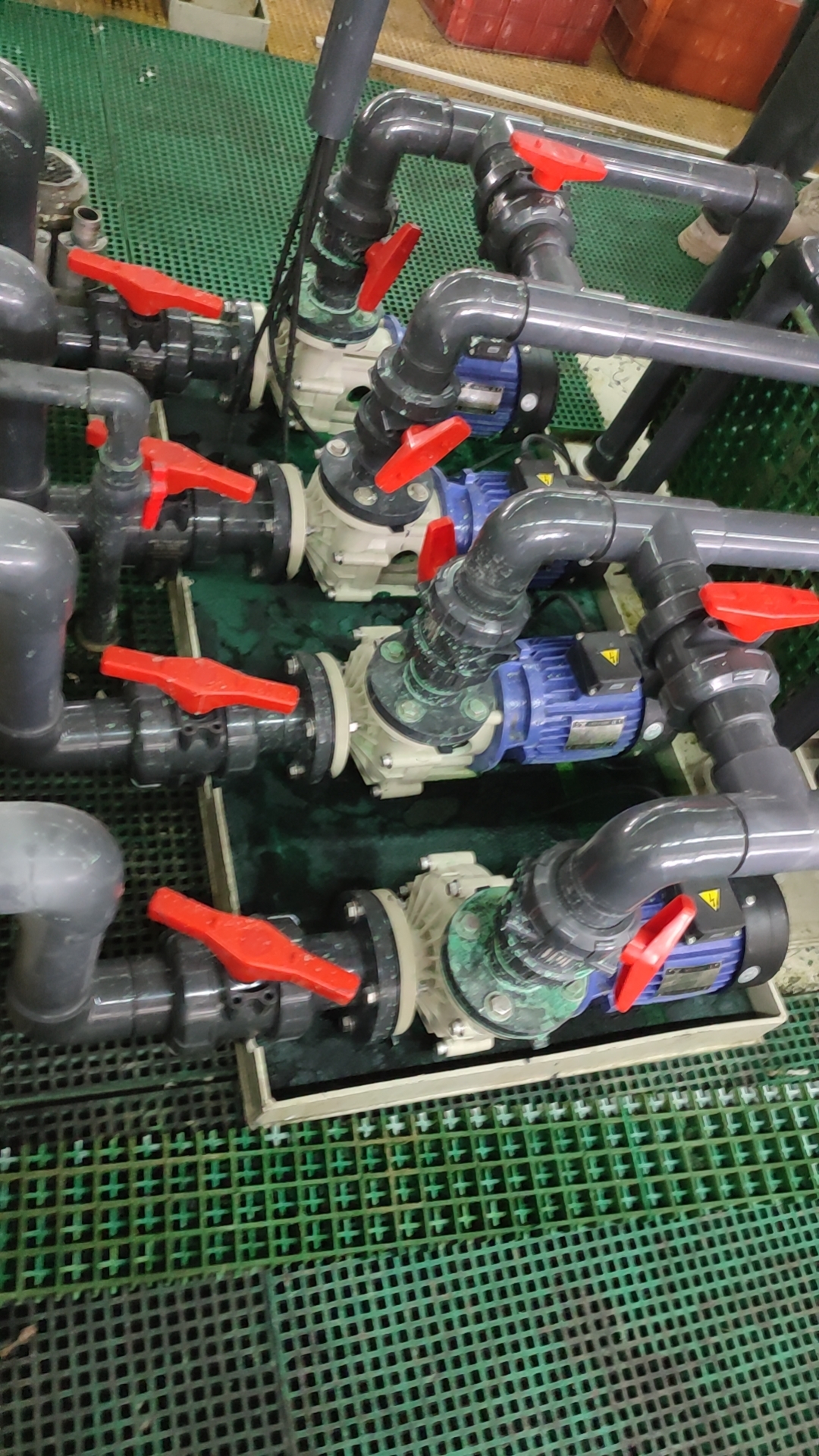

As illustrated in your image showing four major pump types—chemical transfer pumps, acid chemical pumps, chemical-resistant pumps, and chemical wastewater pumps—the world of industrial pumps is built upon precision matching between pump design and the properties of the medium being transported. Below, we explore these four pump types in depth.

1. Chemical Transfer Pump: The Essential Workhorse

Main Role:

The chemical transfer pump is the most fundamental type in industrial processes. It is primarily used to transfer and circulate chemical liquids between containers, storage tanks, or production lines. These fluids are usually stable and only mildly corrosive.

Core Features:

Focuses on efficiency, reliability, and cost-effectiveness. It usually has a compact design, is easy to install and maintain, and ensures smooth operation of production lines.

Typical Applications:

Transferring intermediates from a reactor to a storage tank in chemical plants; precise reagent dosing in laboratories.

2. Acid Chemical Pump: The Corrosion-Resistant Specialist

Core Function:

Designed specifically for handling strong acids such as hydrochloric acid, sulfuric acid, and nitric acid. Acid corrosion is one of the most common and destructive challenges in chemical manufacturing—standard materials fail quickly under such conditions.

Key Technologies:

The material selection defines its success. These pumps are typically made of high-grade stainless steel (e.g., 316L), engineering plastics (e.g., PP, PVDF), or special alloys (e.g., Hastelloy). Many adopt magnetic drive sealing technology to achieve zero leakage, ensuring maximum safety.

Typical Applications:

Electroplating electrolyte circulation, acid transfer in battery production, metal surface acid cleaning lines.

3. Chemical-Resistant Pump: The Versatile Performer

Positioning:

Think of this pump as a multi-resistant all-rounder. It is not only resistant to acids but also capable of handling alkalis, solvents, and various organic chemicals with unpredictable corrosive behaviors.

Main Advantages:

Its greatest strength lies in broad adaptability. With multiple material and seal configuration options, it can be customized based on the medium’s concentration, temperature, and chemical nature—offering the best balance between corrosion resistance and cost.

Typical Applications:

Used in petrochemical plants for solvent transfer, pesticide manufacturing for corrosive raw materials, and research institutes for multipurpose chemical experiments.

4. Chemical Wastewater Pump: The Final Line of Defense

Unique Role:

This pump operates at the end of the production process, handling chemical wastewater and effluents. These fluids often contain suspended solids, oils, toxic substances, and abrasives—making them the toughest challenge for any pump.

Design Priorities:

Focuses on anti-clogging performance, abrasion resistance, and operational reliability. The flow channel is typically larger, and impellers are designed in vortex or single-channel styles to prevent clogging. The pump body materials are selected for high wear resistance to withstand solid particle erosion.

Typical Applications:

Chemical wastewater treatment stations, industrial park effluent lift systems, and high-concentration organic wastewater treatment in environmental projects.

Conclusion

These four pump types together outline a clear selection strategy—start with the properties of your medium.

For general-purpose fluid transfer, choose a chemical transfer pump for its economy and reliability.

For strong acids, the acid chemical pump is your safest choice.

For mixed or unpredictable corrosive fluids, the chemical-resistant pump provides flexibility and durability.

And when dealing with complex, particle-filled wastewater, the chemical wastewater pump is the robust “final guardian.”

Understanding these subtle differences ensures safer, more efficient, and more sustainable industrial operations.