Magnetic drive pumps and centrifugal pumps are both widely used in fluid transfer applications, but they differ significantly in drive mechanism, sealing method, safety level, and maintenance requirements. Understanding these differences helps you choose the right pump for your specific industrial needs.

1. Working Principle

| Aspect | Magnetic Drive Pump | Centrifugal Pump |

|---|---|---|

| Drive Mechanism | Uses magnetic coupling—the motor drives the outer magnet, which transfers torque to the inner magnet through a containment shell. | The impeller is driven directly by a shaft connected to the motor. |

| Sealing Method | Seal-less design; the liquid is completely isolated by a containment shell. | Uses mechanical seal or packing seal, which may lead to leakage over time. |

| Power Transmission | Torque transferred through magnetic field. | Torque transferred mechanically through the shaft. |

2. Structural Design

Magnetic Drive Pump Structure:

Outer magnet, inner magnet, containment shell, impeller

No traditional shaft seal — zero leakage design

Centrifugal Pump Structure:

Impeller, pump shaft, mechanical seal (or packing gland), pump casing

The seal area is the main leakage point

3. Performance Comparison

| Feature | Magnetic Drive Pump | Centrifugal Pump |

|---|---|---|

| Leakage Resistance | ★★★★★ Completely leak-free | ★★★ May leak from mechanical seal |

| Safety & Reliability | Ideal for toxic, flammable, or corrosive fluids | Suitable for clean or neutral liquids |

| Complexity | More complex structure with magnetic components | Simpler structure, easy to repair |

| Efficiency | Slightly lower due to magnetic losses | Generally higher hydraulic efficiency |

| Maintenance | Minimal — no seal replacement needed | Regular maintenance of seals required |

| Cost | Higher initial investment | Lower initial cost |

| Typical Media | Acids, alkalis, solvents, or hazardous fluids | Water, wastewater, and general liquids |

4. Application Fields

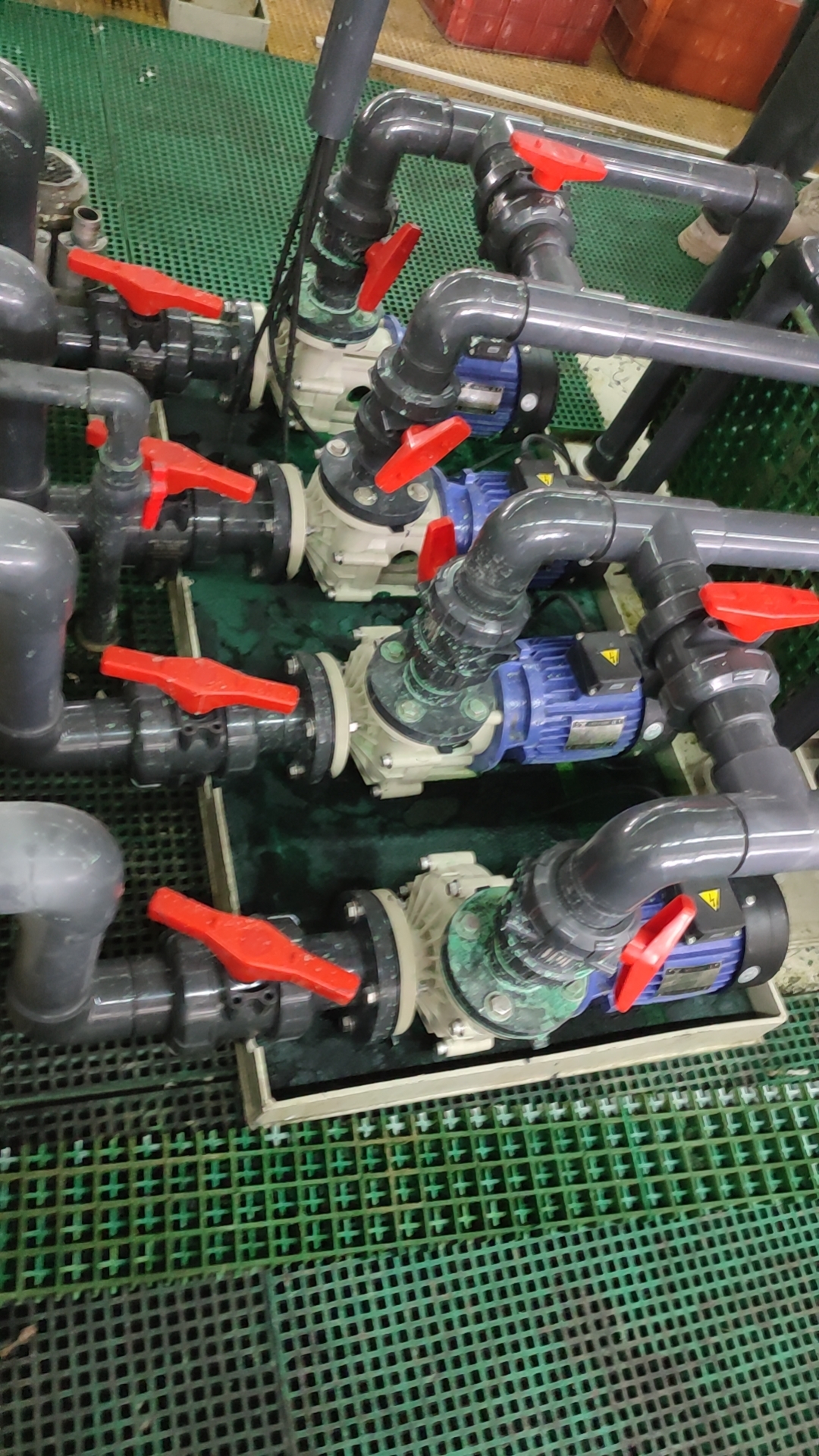

🔹 Magnetic Drive Pump

Best choice for chemical, pharmaceutical, environmental, and electroplating industries, where leak-free and corrosion-resistant operation is essential:

Transfer of strong acids and alkalis (e.g., sulfuric acid, hydrochloric acid, hydrofluoric acid)

Handling toxic, flammable, or volatile chemicals (e.g., benzene, methanol)

High-purity or vacuum systems

🔹 Centrifugal Pump

Commonly used in general industrial and domestic systems:

Cooling water circulation, boiler feed, irrigation

Industrial processes and municipal water supply

5. Summary Table

| Comparison Item | Magnetic Drive Pump | Centrifugal Pump |

|---|---|---|

| Power Transmission | Magnetic coupling | Mechanical shaft |

| Seal Structure | Seal-less | Mechanical or packing seal |

| Leakage Risk | None | Possible |

| Maintenance Cost | Low | Higher |

| Environmental Safety | Excellent | Standard |

| Suitable Applications | Corrosive, toxic, flammable fluids | Clean or neutral liquids |

✅ Conclusion

In essence, a magnetic drive pump is an upgraded version of the centrifugal pump — it maintains the same hydraulic principle but eliminates the shaft seal through magnetic coupling technology, achieving zero leakage and enhanced safety.

If your process involves corrosive, hazardous, or valuable liquids, a magnetic drive pump is the smarter and more sustainable choice.

For clean water or low-risk media, a standard centrifugal pump offers better cost-efficiency and simplicity.