In industries like chemical manufacturing, water treatment, pharmaceutical R&D, and food processing, precise fluid transfer is crucial. Ordinary pumps cannot deliver the accuracy required for applications such as chemical dosing or raw material conveyance. This is where metering pumps come into play. Acting as industrial “dosing specialists,” they provide fluids at preset rates with high precision, forming the backbone of automated and refined production processes.

I. What Is a Metering Pump?

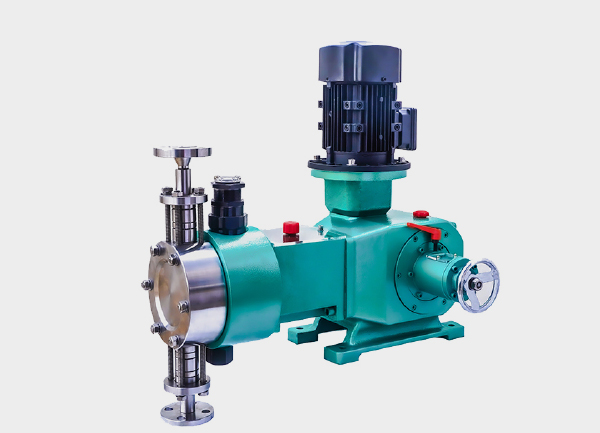

A metering pump (also called a quantitative or proportioning pump) is a specialized positive displacement pump. Its primary function is to transfer fluids continuously or intermittently at precise flow rates under pressure. Most metering pumps allow flexible adjustment of flow rates, typically within a ratio of 1:10 or even 1:100.

Key differences from ordinary pumps:

| Feature | Ordinary Pumps | Metering Pumps |

|---|---|---|

| Purpose | Fluid transfer | Precise dosing |

| Flow Rate Stability | Highly influenced by pressure and resistance | Independent of pressure fluctuations (within rated ranges) |

| Accuracy | Low | ±0.5% to ±3% (high-precision models up to ±0.1%) |

II. How Do Metering Pumps Work?

The secret behind a metering pump is controllable volume change. Through mechanical structures such as plungers, diaphragms, or gears, the pump periodically adjusts its working chamber volume, drawing in fluid and then delivering it in precise quantities.

1. Plunger-Type Metering Pumps

Core Component: Metal plunger

Working Principle:

The plunger reciprocates, driven by a motor.

Retraction expands the chamber, drawing in fluid.

Forward movement squeezes the fluid out.

Pros: Extremely high accuracy (±0.1%–±1%), can handle high pressures

Cons: Mechanical wear due to plunger friction, unsuitable for particulate or highly viscous fluids

2. Diaphragm-Type Metering Pumps

Core Component: Elastic diaphragm (rubber or PTFE)

Working Principle:

A plunger or hydraulic fluid deforms the diaphragm.

Concave diaphragm draws in fluid; convex diaphragm discharges it.

Fluid is completely isolated from mechanical components.

Pros: Leak-free, corrosion-resistant, ideal for toxic or aggressive chemicals

Cons: Slightly lower accuracy (±0.5%–±3%), diaphragms may age under high pressure

3. Gear-Type Metering Pumps

Core Component: Precision gears

Working Principle:

Fluid is trapped between gear teeth and carried to the outlet.

Meshing of gears squeezes the fluid out.

Pros: Stable flow rates, suitable for high-viscosity fluids

Cons: Lower accuracy (±2%–±5%), gears wear easily with particulates

III. Key Features of Metering Pumps

Metering pumps are indispensable due to four core advantages:

Ultra-High Accuracy: Ensures strict proportion control; even ±1% deviation can affect water treatment or pharmaceutical processes.

Flexible Flow Adjustment: Modify stroke length or stroke frequency for precise flow control without changing the pump.

Strong Sealing & Corrosion Resistance: Especially in diaphragm pumps, the fluid is fully isolated, allowing safe handling of acids, alkalis, or toxic solutions.

High Anti-Interference Capability: Flow is stable despite pipeline pressure or fluid viscosity changes.

IV. Applications of Metering Pumps

Metering pumps are widely used wherever precise dosing or fluid transfer is required:

Water Treatment:

Add flocculants and disinfectants (e.g., sodium hypochlorite).

Neutralize pH and remove contaminants in sewage plants.

Chemical & Petrochemical Industries:

Inject catalysts, solvents, corrosion inhibitors, and demulsifiers with precision.

Pharmaceutical & Food Industries:

Convey drug ingredients with ±0.1% accuracy.

Add preservatives and flavors without leakage.

Agriculture & Environmental Protection:

Prepare precise pesticide solutions.

Spray absorbents to neutralize waste gas in industrial scrubbers.

V. How to Select the Right Metering Pump

Consider five key factors:

Flow Rate: Choose a pump with 10%–20% margin above the required rate.

Pressure: Pump rated pressure must exceed pipeline pressure.

Fluid Properties:

Corrosive → PTFE diaphragm pumps

Viscous → Gear pumps

Particulates → Diaphragm pumps with filters

Accuracy Requirements:

High precision (±0.1%–±1%) → Plunger pumps

Moderate precision (±0.5%–±3%) → Diaphragm pumps

Control Method:

Automated → Frequency conversion or PLC interface

Manual → Mechanical knob adjustment

VI. Maintenance Tips to Extend Lifespan

Leak Checks: Inspect pump heads and joints regularly; replace seals promptly.

Avoid Dry Running: Always fill the pump before operation.

Cleaning & Lubrication: Lubricate plungers; rinse after corrosive fluids.

Flow Calibration: Calibrate every 3–6 months with a flowmeter; adjust stroke length or frequency if needed.

Conclusion:

Though compact in size, metering pumps are unsung heroes of precision industrial production. Their combination of accurate metering, controllable adjustment, and corrosion resistance ensures safe and reliable fluid transfer across water treatment, pharmaceuticals, food processing, chemical industries, and more. Understanding their working principles and features is key to selecting the right pump for any precise dosing task.