Both pneumatic diaphragm pumps (PDP) and electric diaphragm pumps (EDP) belong to the diaphragm pump family. Their core function is the reciprocating movement of a diaphragm to transport fluids. However, due to different power sources, they differ significantly in structure, performance, and suitable applications. This guide compares the two types across key dimensions to help you make the right selection.

1. Core Difference: Power Source & Working Principle

The fundamental difference lies in how the diaphragm is driven, which affects all other characteristics:

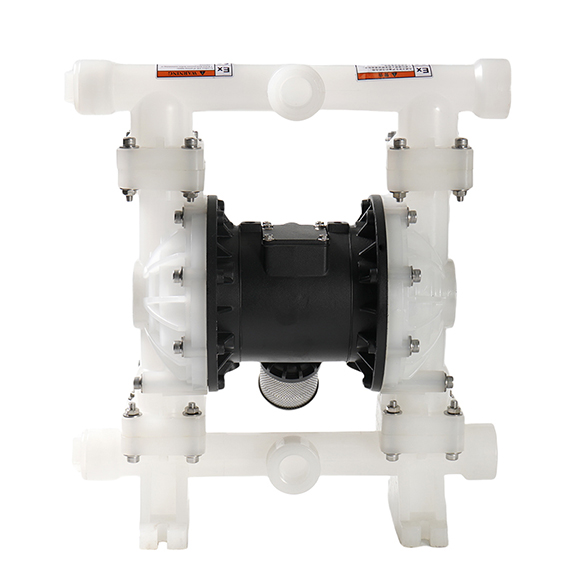

1.1 Pneumatic Diaphragm Pump (PDP)

Power Source: Compressed air (requires an air compressor and air treatment unit).

Working Principle: An air distribution valve alternately sends compressed air to the two diaphragm chambers, causing the diaphragms to reciprocate. When one diaphragm pushes fluid out, the other creates suction, achieving continuous flow.

Key Features:

Built-in overload protection: automatically stops when air pressure is too high, no risk of damage.

Dry-running capability: can run without fluid without damage.

1.2 Electric Diaphragm Pump (EDP)

Power Source: Electric energy (AC 220V/380V or DC 12V/24V).

Working Principle: An electric motor + gearbox drives a crank or cam, converting rotary motion into linear reciprocating motion that drives the diaphragm to pump fluid.

Key Features:

Requires external overload protection (e.g., thermal relay).

Dry-running can damage the diaphragm and burn out the motor.

2. Key Comparison: Pneumatic vs Electric Diaphragm Pumps

| Feature | Pneumatic Diaphragm Pump (PDP) | Electric Diaphragm Pump (EDP) |

|---|---|---|

| Power Requirement | Compressed air; works without electricity | Electricity; works without air source |

| Structural Complexity | Simple (diaphragm + air valve) | Complex (motor, gearbox, crank/rod, seals) |

| Overload Protection | Built-in (automatic shutdown under high air pressure) | Requires external device (thermal relay, fuse) |

| Dry-Running Capability | Yes, safe | No, risks diaphragm and motor damage |

| Explosion-Proof Safety | Natural (no electric spark) | Requires special design (explosion-proof motor + sealing) |

| Flow & Pressure Stability | Affected by air pressure fluctuations | Stable (motor speed fixed) |

| Lift & Flow Range | Lower (≤100 m, ≤100 m³/h) | Higher (≤200 m, ≤200 m³/h) |

| Noise Level | Higher (exhaust noise, requires silencer) | Lower (motor noise only) |

| Maintenance Cost | Low (replace diaphragm + air valve) | Higher (motor, bearings, gearbox) |

| Initial Investment | High (air compressor + piping required) | Low (pump only, no air system) |

| Typical Applications | Explosion-proof, mobile, dry-run, corrosive fluids | Fixed site, stable flow, indoor, low-noise |

3. Suitable Applications

3.1 Pneumatic Diaphragm Pump

Hazardous environments: Chemical plants, oilfields (methanol, ethanol, crude oil) — no sparks, naturally explosion-proof.

No electricity or mobile sites: Outdoor construction, mining (air compressor powered).

Intermittent or dry-running fluids: High-viscosity fluids or slurry (paints, mortar).

Corrosive fluids: PTFE or other resistant diaphragms, no motor seals to corrode.

3.2 Electric Diaphragm Pump

Fixed sites with power supply: Water treatment (chemical dosing), food processing (juices, sauces), labs.

Stable flow & pressure: Metering, irrigation systems — motor speed is fixed, flow steady.

Low-noise requirement: Indoor factories, hospitals.

Lower initial cost: Small workshops, home use — no air compressor required.

4. Selection Guidelines

Choose Pneumatic Diaphragm Pump if:

Explosion-proof is required.

No electricity is available or mobile operation needed.

Fluids are intermittent or dry-run is possible.

Air compressor is already available.

Choose Electric Diaphragm Pump if:

Fixed location with power supply.

No explosion-proof requirement.

Stable flow/pressure is required.

Low noise is important.

Budget is limited (no air system needed).

Special Note:

For high-viscosity (>1000cP) or large particle fluids (>5 mm) → Prefer pneumatic pump (less clogging, safe dry-run).

For small, precise metering (mL-level dosing) → Prefer electric pump (stable, controllable flow).