Chemical pumps are essential for transferring various liquids in industries such as chemical processing, petrochemicals, and pharmaceuticals. Their temperature and pressure limits depend on design, materials, sealing methods, and the properties of the handled medium. Below is a detailed overview of how these factors define the working range of chemical pumps.

🌡️ 1. Temperature Range

1.1 Normal-Temperature Chemical Pumps

Operating Temperature: 0–80°C

Typical Materials: Stainless steel, engineering plastics (PP, PVC, PVDF)

Applications: Common chemical liquids, acid and alkali solutions, water treatment chemicals.

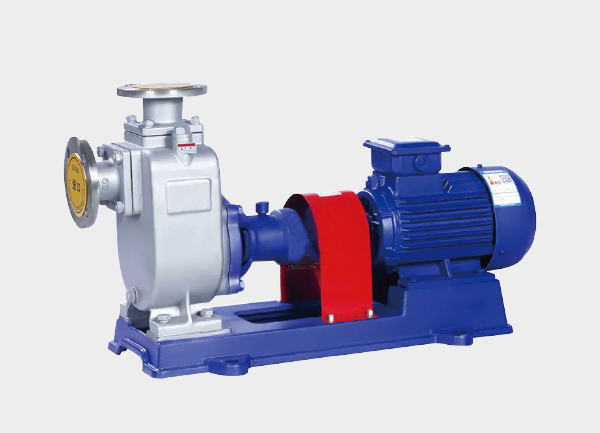

Typical Pump Types: Plastic magnetic drive pumps, centrifugal pumps, self-priming pumps.

1.2 Medium-Temperature Chemical Pumps

Operating Temperature: 80–150°C

Typical Materials: Stainless steel 304/316L, fluoroplastic-lined metal, cast iron

Sealing Options: Mechanical seal or magnetic drive

Applications: Alcohols, ketones, organic solvents, hot water, and low-temperature oils.

Typical Pump Types: Stainless steel centrifugal pump, magnetic pump, high-temperature self-priming pump.

1.3 High-Temperature Chemical Pumps

Operating Temperature: 150–350°C (some special models up to 450°C)

Typical Materials: Stainless steel, carbon steel, high-temperature alloys (Hastelloy, titanium alloy)

Sealing Options: High-temperature mechanical seal or magnetic isolation drive

Cooling Methods: Natural cooling, water cooling, or air cooling

Applications: Heat transfer oil, benzene, hydrocarbons, petrochemical thermal systems.

Typical Pump Types: High-temperature magnetic drive pump, heat transfer oil pump, high-temperature centrifugal pump.

1.4 Low-Temperature Chemical Pumps

Operating Temperature: -80–0°C

Typical Materials: Stainless steel, low-temperature steel, aluminum alloy

Applications: Liquid ammonia, liquid nitrogen, liquid oxygen, cryogenic ethylene transfer.

Typical Pump Types: Cryogenic centrifugal pump, cryogenic magnetic pump, liquefied gas pump.

⚙️ 2. Pressure Range

| Pump Type | Typical Pressure Range (MPa) | Description |

|---|---|---|

| Plastic magnetic pump / plastic centrifugal pump | ≤0.6 MPa | Suitable for low-pressure, highly corrosive media. |

| Stainless steel centrifugal pump | 0.6–1.6 MPa | Most common in general chemical applications. |

| Multistage high-pressure pump | 1.6–10 MPa | Used for long-distance or high-head systems. |

| High-temperature magnetic or thermal oil pump | 0.6–2.5 MPa | Designed to handle thermal expansion safely. |

| Plunger and diaphragm pumps | Up to 40 MPa | Used for laboratory and high-pressure process systems. |

🧰 3. Selection Guidelines

For fluids above 120°C → Choose high-temperature magnetic or thermal oil pumps.

For strong corrosive liquids → Use fluoroplastic pumps (PVDF, PTFE).

For high pressure or long-distance transfer → Select multistage centrifugal or diaphragm pumps.

For cryogenic liquids → Ensure low-temperature materials and flexible seals are used.

🌍 4. Summary

The temperature range of chemical pumps generally spans from -80°C to +350°C, while their pressure capacity ranges from 0.1 MPa to over 10 MPa. Material choice and design structure directly affect their performance under extreme conditions.

Selecting the right chemical pump—whether a magnetic drive pump, centrifugal pump, or thermal oil pump—is crucial for ensuring safety, reliability, and extended service life in chemical processing systems.