1. Importance of Centrifugal Pumps in Mining Drainage

During mining operations, groundwater infiltration is a common challenge, especially in underground mines, open-pit mines, and tunnel constructions. Accumulated water can disrupt production, damage equipment, and pose serious safety risks.

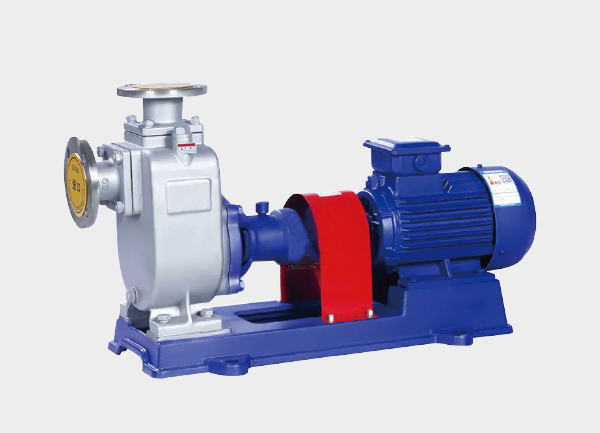

To ensure safe and efficient operations, centrifugal pumps have become the most widely used and essential equipment in mine drainage systems.

By using the centrifugal force generated by a rotating impeller, these pumps effectively transport water from low to high elevations. They are known for their simple structure, high efficiency, large flow capacity, and easy maintenance, making them ideal for continuous and large-scale dewatering tasks.

2. Main Applications of Centrifugal Pumps in Mining

Underground Mine Drainage

In underground mining, centrifugal pumps are used to remove accumulated or inflowing groundwater from mine shafts. Multistage centrifugal pumps with high head capabilities are commonly used to handle the deep and high-pressure drainage requirements.Open-Pit Mine Dewatering

Open-pit mines often face flooding due to rainfall or groundwater seepage. Portable or fixed centrifugal pump stations are installed to discharge excess water and keep the pit area dry for equipment operation and excavation.Concentrator and Tailings Water Handling

In ore concentration and tailings processing plants, centrifugal pumps are used to transport slurries, tailing water, and other mixtures. Special wear-resistant and corrosion-resistant models are employed to handle abrasive fluids.Temporary Dewatering During Tunneling or Excavation

During mine construction and tunneling, centrifugal pumps are used for temporary drainage to prevent flooding in working areas and ensure operational safety.

3. Common Types of Centrifugal Pumps Used in Mining

| Pump Type | Main Features | Typical Application |

|---|---|---|

| Single-stage centrifugal pump | Simple design, large flow rate | Open-pit mine dewatering, short-distance transfer |

| Multistage centrifugal pump | High head, stable performance | Deep mine shaft main drainage |

| Slurry or gravel pump | Wear-resistant design with alloy or rubber lining | Slurry, sand-water, and tailings drainage |

| Submersible centrifugal pump | Compact, can operate underwater | Deep shaft or confined-space dewatering |

4. Advantages of Using Centrifugal Pumps in Mining Drainage

High and Reliable Efficiency

Capable of continuous 24/7 operation, ensuring stable mine dewatering performance.Compact Structure and Easy Maintenance

Key components such as impellers, casings, and seals are easy to inspect, repair, or replace.Adaptability to Harsh Conditions

Pumps with anti-corrosion, explosion-proof, or wear-resistant materials can operate reliably in high humidity, high temperature, or abrasive environments.Automation and Energy Efficiency

Modern mining drainage systems often integrate automatic controls and variable frequency drives (VFDs) for real-time monitoring and intelligent energy management.

5. Key Operation and Maintenance Tips

Regularly check seals and bearings to prevent leakage or wear.

Ensure the suction inlet is free of blockage and maintain good water inflow.

Select the right pump model and head to avoid cavitation or overloading.

For abrasive or corrosive fluids, use pumps with wear-resistant materials or protective coatings.

6. Conclusion

Centrifugal pumps play a vital role in mine drainage, ensuring both operational safety and production efficiency. With ongoing advancements in automation and material technology, mining centrifugal pumps are evolving toward higher efficiency, smarter control, and greater durability.

Their proven reliability and adaptability make them an indispensable part of modern mining operations.