Chemical pumps play a vital role in chemical processing, transferring corrosive, viscous, or high-temperature fluids safely and efficiently. However, under harsh operating conditions, their components often face corrosion, wear, and sealing failures. This article explains in detail how to extend the service life of chemical pumps through proper selection, installation, operation, and maintenance practices.

1. Proper Pump Selection Is the Foundation

Match the Pump Type to the Medium

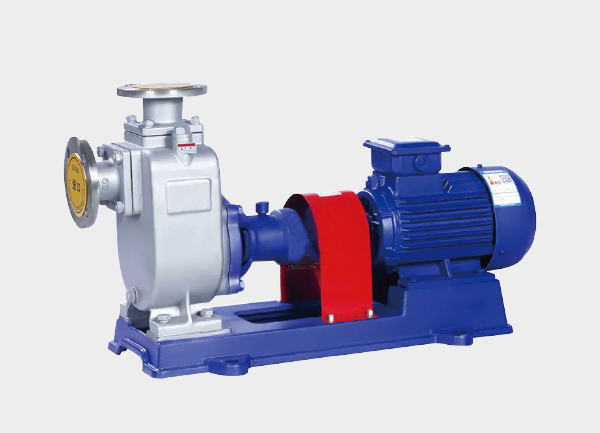

Corrosive fluids: Use fluoroplastic pumps, lined chemical pumps, or stainless steel magnetic drive pumps for superior corrosion resistance.

High-temperature fluids: Select high-temperature magnetic drive pumps or mechanical-seal centrifugal pumps with proper cooling systems.

Viscous or particle-containing media: Choose open-impeller pumps, screw pumps, or diaphragm pumps to prevent clogging and wear.

Avoid Oversized or Undersized Pumps

The pump’s rated flow and head should closely match the actual system conditions. Overloading or underloading leads to bearing, impeller, and seal failures.

Select the Right Sealing System

For toxic or corrosive liquids: use magnetic drive pumps with sealless design.

For high-pressure or abrasive applications: use reinforced mechanical seals or double-seal configurations.

2. Correct Installation and Commissioning

Stable Foundation and Accurate Alignment

Ensure the motor and pump shafts are properly aligned — the misalignment tolerance should not exceed 0.1 mm. Poor alignment leads to premature bearing and coupling wear.

Proper Piping Layout

Suction piping should be short, straight, and airtight to prevent cavitation.

The discharge line should include a check valve and shut-off valve to prevent backflow and water hammer.

Adequate Cooling and Lubrication

Mechanical seals and magnetic isolation sleeves must have reliable cooling circulation.

Check lubricant levels in sliding bearings regularly to avoid dry friction and overheating.

3. Optimize Operating and Maintenance Conditions

Avoid Dry Running and Frequent Starts

Dry running can destroy seal faces, burn the containment shell, and damage bearings.

Maintain Stable Operating Conditions

Operate near the pump’s best efficiency point (BEP) to minimize vibration and mechanical stress. Avoid extreme low-flow or high-flow conditions.

Conduct Regular Inspections

Monitor vibration, temperature, noise, and leakage.

Inspect bearings, seals, and impellers periodically.

Address abnormal vibration or reduced flow immediately to prevent secondary damage.

Keep the Fluid Clean

Install filters or strainers on the suction side. Remove solid particles or crystallized material that can cause blockage or abrasion.

4. Material and Spare Parts Management

Use Genuine Spare Parts

Always use original mechanical seals, bearings, and O-rings to ensure chemical compatibility and performance.

Replace Worn Components on Schedule

Replace wear-prone parts like seals, isolation sleeves, and bearings based on operating hours or service cycles.

Apply Anti-Corrosion Protection

For pumps handling aggressive chemicals, use protective coatings or anodic protection to slow down corrosion and extend service life.

5. Establish a Maintenance and Management System

Maintain Detailed Operation Records

Keep logs of running data, maintenance history, and failure analysis to identify trends and predict potential issues.

Implement Preventive Maintenance Programs

Routine inspection and timely replacement of parts help reduce unplanned shutdowns and repair costs.

Train Operators and Maintenance Staff

Ensure personnel understand the correct startup and shutdown sequences, emergency procedures, and fault identification techniques.

6. Summary

| Key Stage | Tips to Extend Pump Life |

|---|---|

| Selection | Choose pump type, material, and seal according to medium and temperature |

| Installation | Ensure alignment, proper piping, and cooling systems |

| Operation | Keep stable flow, avoid dry running or overloading |

| Maintenance | Replace worn parts, check lubrication and corrosion regularly |

| Management | Maintain records, perform preventive maintenance, train staff |

By combining proper design, correct installation, stable operation, and systematic maintenance, you can extend the service life of a chemical pump by 30% to 50%, improve system reliability, and reduce total operating costs.