In industries such as chemical processing, pharmaceuticals, environmental protection, electroplating, and wastewater treatment, the stainless steel vertical sump pump has become one of the most trusted liquid transfer solutions.

With its outstanding corrosion resistance, compact structure, and reliable performance, this pump is increasingly recognized as an essential piece of equipment for modern industrial systems.

1. Structural Advantage – Space-Saving and Stable Operation

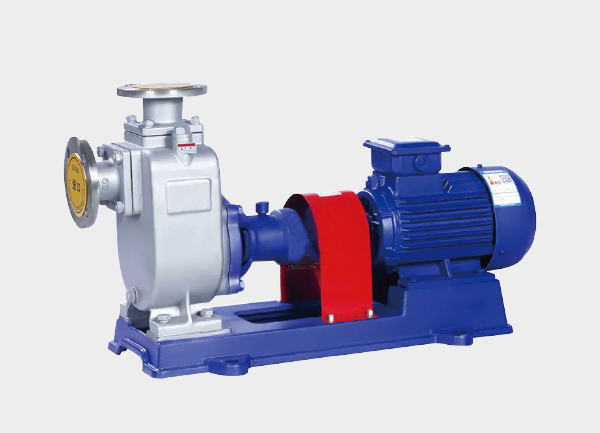

The stainless steel vertical sump pump features a vertical installation design, with the pump body submerged in liquid and the motor positioned above the liquid level.

This layout not only saves valuable floor space but also prevents the motor from being exposed to corrosive vapors.

Additionally, the vertical configuration reduces inlet pipe resistance, resulting in higher efficiency, smoother operation, and improved reliability.

2. Material Advantage – Corrosion Resistant and Long-Lasting

As its name suggests, the biggest strength of this pump lies in its stainless steel construction.

High-quality stainless steel such as 304 or 316L offers exceptional resistance to acids, alkalis, and oxidation, allowing the pump to perform reliably even in high-temperature or highly corrosive environments.

Compared with pumps made of carbon steel or other materials, stainless steel vertical sump pumps provide longer service life and superior operational safety.

3. Performance Advantage – Self-Priming and Easy Maintenance

The stainless steel vertical sump pump does not require priming or pre-filling before startup — it is ready to operate immediately, making it ideal for underground tanks, sumps, and deep wells.

Since the motor and bearings are located above the liquid surface, routine inspection, lubrication, and maintenance are simple and convenient, helping companies reduce downtime and maintenance costs.

4. Choosing a Reliable Manufacturer – The Key to Long-Term Performance

When selecting a stainless steel vertical sump pump, it’s important to consider not just flow rate and head, but also the manufacturer’s precision engineering and quality control capabilities.

For instance, Xiaojuren Pump Industry specializes in chemical pumps, magnetic drive pumps, and vertical sump pumps. With advanced manufacturing technology and strict testing standards, Xiaojuren ensures that every pump operates efficiently, safely, and reliably under demanding industrial conditions.

Conclusion:

The stainless steel vertical sump pump offers industries a safer and more efficient solution for handling corrosive liquids.

By solving the problems of leakage, corrosion, and maintenance complexity, it has become the ideal choice for modern chemical and environmental applications, combining high strength, low maintenance, and long service life in one durable design.