In modern industrial processes, sealless magnetic drive pumps are becoming essential components in fluid transfer systems. Compared to traditional submerged pumps, their unique design and exceptional performance are redefining standards for efficient and safe fluid handling.

What Are Sealless Magnetic Drive Pumps?

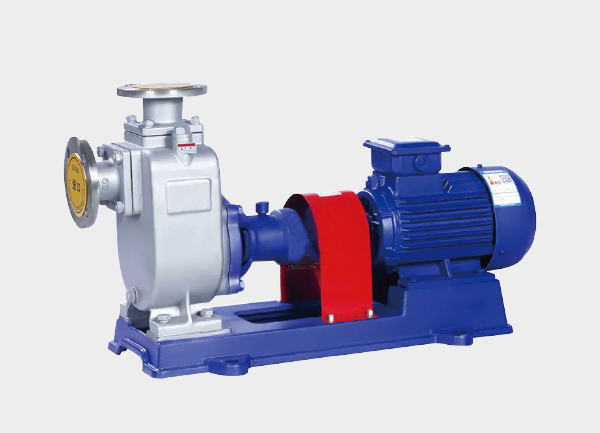

As the name suggests, these pumps are installed externally to tanks or containers, connected via piping to enable fluid extraction and transfer. This independent installation method brings numerous groundbreaking advantages.

Five Core Advantages of Magnetic Drive Pumps

1. Zero Leakage Guarantee

Utilizing advanced magnetic drive technology, they achieve 100% static sealing. This fundamentally eliminates leakage risks during operation, providing an intrinsically safe solution for chemical, electroplating, and other sensitive industries.

2. Exceptional Corrosion Resistance

Wetted parts can be constructed from specialty engineering plastics like PP or PVDF, easily handling various strong acids, alkalis, and organic solvents, significantly extending equipment service life.

3. Minimal Maintenance Requirements

Quick Disassembly: Pump body can be detached in minutes without draining the tank

Online Maintenance: Does not affect other equipment operation, drastically reducing downtime

Modular Design: Standardized interfaces allow for simple, fast replacement of components

4. Significant Energy Savings

Optimized hydraulic models paired with high-efficiency motors can reduce energy consumption by up to 30% compared to conventional pumps, offering substantial long-term operational cost advantages.

5. Excellent Adaptability

Unconstrained by tank structure or installation position, they can be flexibly arranged according to site conditions, easily accommodating renovation and expansion projects.

Typical Application Scenarios

Chemical Industry: Circulation and transfer of various acids, alkalis, and chemical solutions

Electroplating Lines: Precise transfer of plating solutions and rinse water

Environmental Engineering: Collection and treatment of wastewater and spent liquids

Pharmaceutical Sector: Sterile transfer of process fluids

Conclusion

Sealless magnetic drive pumps not only solve the leakage and maintenance challenges of traditional pumps but also represent the ideal choice for modern production with their superior adaptability. Choosing magnetic drive pumps means opting for safer, more economical, and more efficient production methods.